Exploring The Properties, Manufacturing, And Applications Of Gadolinium Gallium Garnet

Introduction

Garnets belong to the mineral group A3B2(SiO4)3. They exhibit uniform physical properties and crystal structures. They are employed as gemstones, substrates and abrasives. However, garnets differ in chemical composition. This article addresses the garnet family with a focus on Gadolinium-Gallium Garnet (GGG) and reviews its properties, production method and applications. The text provides a basic understanding of this versatile material.

Definition of Gadolinium-Gallium Garnet

Gadolinium-gallium garnet (Gd3Ga5O12) is a synthetic garnet with well-defined thermal, mechanical and optical properties.

- Gadolinium-gallium garnet (GGG) has a thermal conductivity of 7,4 W m⁻¹K⁻¹ and a melting point of approximately 1 730℃.

- The material has a Mohs hardness ranging from 6,5 to 7,5.

- GGG exhibits an optical loss of less than 0,1 %/cm. It is transparent for optical components between 0,36 and 6,0 μm, and its refractive index ranges from 2,0 in the ultraviolet region to 1,8 in the infrared region.

Production of Gadolinium-Gallium Garnet

The Czochralski method is a well-established technique for growing single crystals, including Gadolinium-Gallium Garnet (GGG). Jan Czochralski, a Polish scientist, discovered this method when a seed was inadvertently immersed in molten tin. This observation led to its adoption for single crystal production.

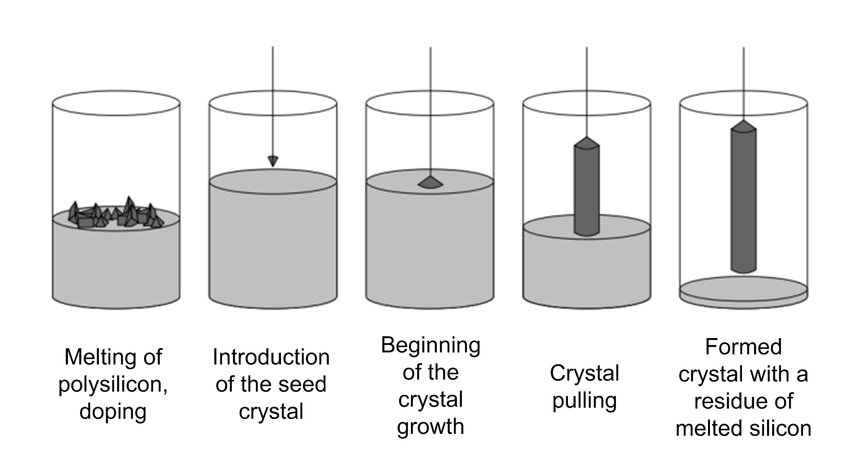

Figure 1 presents a schematic diagram of the Czochralski process as applied to silicon crystal production.

The process comprises the following steps:

-

The starting material is heated in a round crucible until it is completely molten.

-

A seed crystal is carefully introduced into the melt while being rotated slowly, thereby initiating crystal formation.

-

The seed crystal is slowly withdrawn from the melt, and a single crystal develops at the interface.

The Czochralski method requires precise control over process parameters. Temperature, rotation speed and withdrawal speed are monitored to ensure the desired crystal quality and shape. An inert atmosphere is maintained to prevent contamination and oxidation.

Dopants may be added to adjust colour or other specific properties. The method is also used for the production of semiconducting materials such as silicon and gallium arsenide.

Applications of Gadolinium-Gallium Garnet

Gadolinium-gallium garnet is employed in various sectors due to its precisely determined properties. It is used as a substrate material for magneto-optical layers. Depositing a Yttrium-Iron Garnet film on a GGG substrate facilitates the production of optical infrared isolators.

GGG is used as a carrier for magnetic bubble memory, given that its lattice parameter closely matches that of the storage material. GGG crystals are also employed as substrates for microwave isolators.

During the 1970s, GGG was used as a diamond simulant owing to its optical resemblance to natural diamonds. It was subsequently replaced by Yttrium-Aluminium Garnet (YAG) because YAG exhibits a higher hardness. GGG continues to be selected when a diamond-like appearance is required.

Other Garnet Materials

Our website provides several options for synthetic garnets. One option is Cerium-doped Gadolinium-Aluminium-Gallium Garnet (Ce:GAGG). It displays a high light yield, a rapid scintillation response, chemical stability and high energy resolution. Ce:GAGG is suitable for X‑ray imaging, computerised tomography (CT) and other medical imaging techniques.

Another option is Neodymium-doped Yttrium-Aluminium Garnet (Nd:YAG), which demonstrates high optical absorption and energy conversion efficiency. Nd:YAG is used in laser marking devices, cosmetic instruments and cutting machines.

Please visit our homepage for further information.

Further details: An Introduction to 7 Types of Synthetic Garnet Materials

Conclusion

Gadolinium-Gallium Garnet (GGG) is a material with defined properties, including a high melting point, thermal conductivity, hardness and measured optical characteristics. At Stanford Advanced Materials (SAM) we offer high-purity garnets in various diameters to meet specific requirements. If you are interested, please send us an enquiry and we will provide further assistance.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento